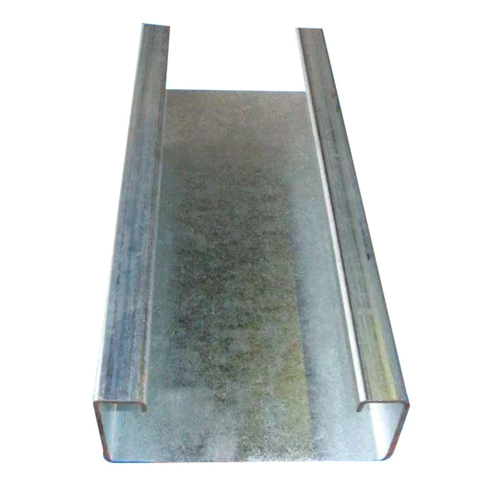

Heavy-Duty and Affordable Mild Steel Hot Dip Galvanizing Pipe, Grey Hot Dip

Galvanizing Chain, Steel Hot Dipped Galvanized Angle, Galvanized Earthing Strip,

etc.

Established in 2014 in the vibrant industrial hub of Mumbai,

Maharashtra, R S Industrial Corporation has emerged as a trusted name in

the field of manufacturing, trading, supplying, and service provision.

With a strong focus on quality, durability, and customer satisfaction,

we serve a wide array of industries requiring reliable galvanized steel

products and surface treatment services.

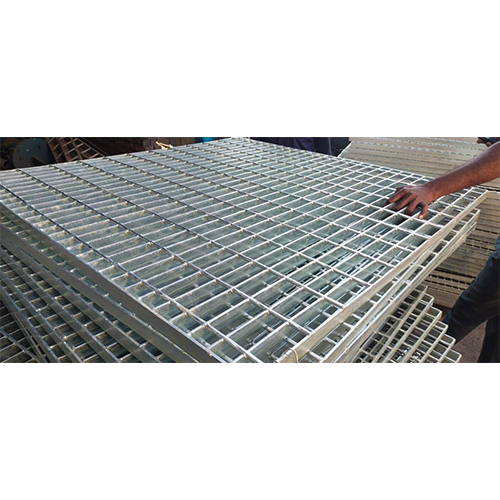

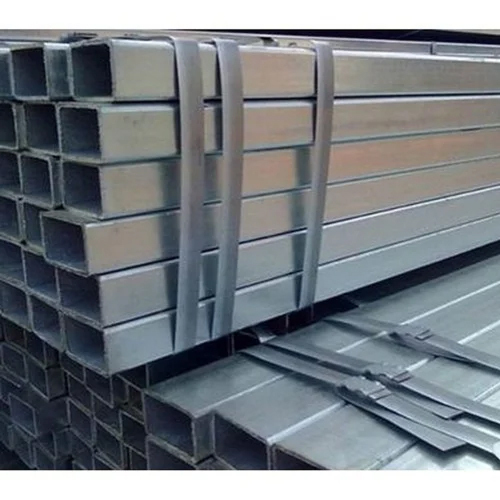

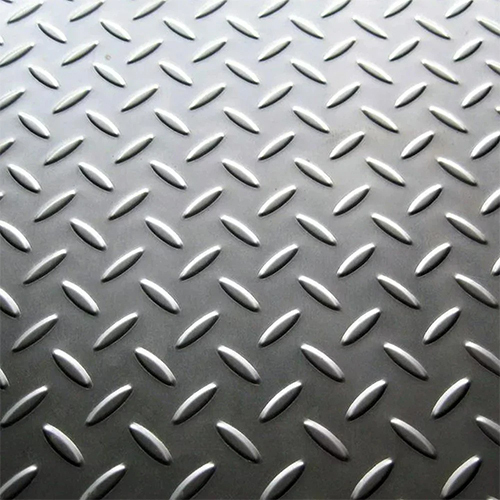

Over the years, we have built a solid reputation for delivering high-performance products that meet stringent industry standards. As a dedicated manufacturer and supplier, we specialize in a comprehensive range of hot dip galvanized steel components, known for their superior corrosion resistance and long service life.

Our core product offerings include Mild Steel Hot Dip Galvanizing Pipe, Grey Hot Dip Galvanizing Chain, Steel Hot Dipped Galvanized Angle, Galvanized Earthing Strip, etc. We also provide Industrial Shot Blasting Services, Hot Dip Galvanizing Services, etc.

Our Team

At the heart of our company is a team of experienced professionals, including engineers, technicians, and quality inspectors, all committed to innovation, precision, and customer satisfaction. We work closely with our clients to understand their unique needs and provide customized solutions that align with project specifications and industry guidelines.

Modern Manufacturing Facility

Our manufacturing unit is fully equipped with advanced machinery and equipment required for the fabrication and hot dip galvanizing of mild steel components. Key features of our production setup include:

We follow a rigorous quality control system at every stage, from raw material inspection to final product dispatch. This ensures that all products meet industry specifications and withstand environmental wear and tear.

Over the years, we have built a solid reputation for delivering high-performance products that meet stringent industry standards. As a dedicated manufacturer and supplier, we specialize in a comprehensive range of hot dip galvanized steel components, known for their superior corrosion resistance and long service life.

Our core product offerings include Mild Steel Hot Dip Galvanizing Pipe, Grey Hot Dip Galvanizing Chain, Steel Hot Dipped Galvanized Angle, Galvanized Earthing Strip, etc. We also provide Industrial Shot Blasting Services, Hot Dip Galvanizing Services, etc.

Our Team

At the heart of our company is a team of experienced professionals, including engineers, technicians, and quality inspectors, all committed to innovation, precision, and customer satisfaction. We work closely with our clients to understand their unique needs and provide customized solutions that align with project specifications and industry guidelines.

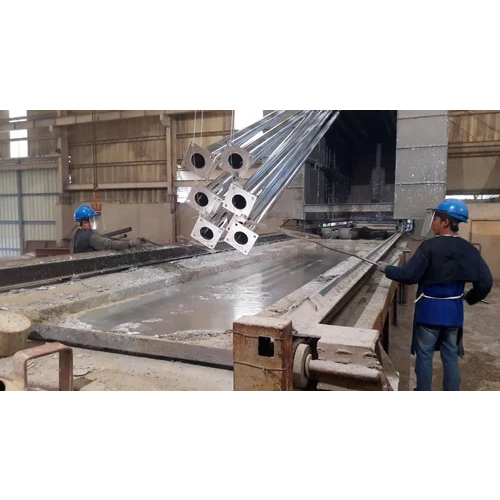

Modern Manufacturing Facility

Our manufacturing unit is fully equipped with advanced machinery and equipment required for the fabrication and hot dip galvanizing of mild steel components. Key features of our production setup include:

- Hot Dip Galvanizing Plant with controlled temperature zinc kettles for uniform coating

- Pre-treatment tanks for degreasing, pickling, and fluxing processes

- Fabrication machinery such as cutting, bending, and welding tools for steel structures

- Shot blasting equipment for superior surface preparation before galvanizing

- Quality testing instruments to check coating thickness, adhesion, and finish

We follow a rigorous quality control system at every stage, from raw material inspection to final product dispatch. This ensures that all products meet industry specifications and withstand environmental wear and tear.